On July 13, it was reported that the main structure of the Mulei CO₂ energy storage project by China Huadian Corporation was successfully topped out on July 10, laying the foundation for subsequent equipment installation and commissioning work.

This project is a demonstration project of new energy storage supporting the construction of large-scale wind and solar bases in desert, Gobi, and arid regions. It is planned to have an installed capacity of 600,000 kW of wind power, 400,000 kW of photovoltaic power, and 1,000,000 kWh of energy storage, making it the world’s largest CO₂ energy storage project.

The project is located in Western China. It involves the construction of one set of compressed CO₂ energy storage system with an energy storage duration of 8 hours and a power generation duration of 10 hours, adopting a non-combustion compressed CO₂ energy storage process system.

What is CO₂ energy storage?

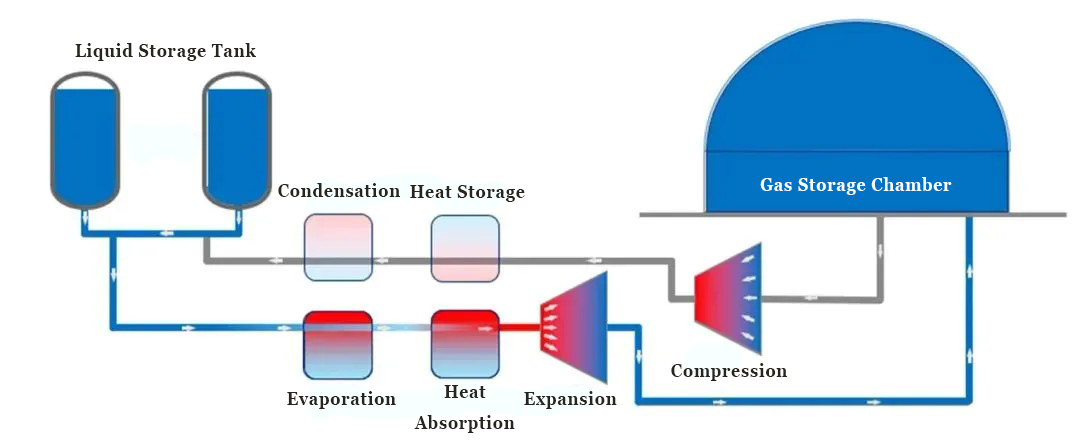

Energy storage phase:

During periods of electricity surplus, atmospheric pressure gaseous CO₂ is compressed, the compression heat is stored, and the high-pressure CO₂ is liquefied at ambient temperature for storage.

Power generation phase:

Stored heat is used to heat the high-pressure liquid CO₂ into high-temperature gas to drive a turbine for power generation.

What are the advantages of CO₂ energy storage?

CO₂ energy storage systems offer multiple advantages in large-capacity, long-duration, and safety-related energy storage applications—

Environmentally friendly

CO₂ operates within a closed system with minimal environmental impact, and the entire process consists of physical changes, producing no pollutants.

No special geological conditions required

Does not require underground space, has good site adaptability, and does not depend on specific geological conditions.

Short construction period, long lifespan, zero carbon emissions

Approximately 2-year construction period, service life exceeding 30 years, non-combustion, zero carbon emissions, and low levelized cost of electricity over the full lifecycle.

Constant pressure operation throughout the entire process

The system runs at constant pressure across all time periods, with rotating machinery operating for extended periods under rated conditions, resulting in high system efficiency.

Meets grid dispatching requirements

Equipment such as compressors, expanders, and heat exchangers can start and stop quickly in a short time, promptly responding to grid dispatching needs.

Provides ancillary services

Can provide rotational inertia support to the grid and offer ancillary services such as peak shaving and frequency regulation.

Controllable industry chain

All subsystems and key core equipment are independently developed and are safe and controllable.