By | cnenergynews.cn

Recently, it was learned that the excavation of the underground gas storage cavern at the 300MW advanced compressed air energy storage national demonstration power station being built by China National Energy (Beijing) Technology Co., Ltd. in Xinyang, Henan, has been successfully completed by 50%. This marks an important phased progress in the construction of China’s first 300,000 m³ large-scale gas storage.

When it comes to a 300,000 m³ underground gas storage cavern, people may have no concept. But if converted, it is equivalent to the volume of 130 Olympic-standard swimming pools filled with water, and you, like me, will be astonished.

So why build an underground gas storage cavern of such scale, and what does it mean for compressed air energy storage?

It is no exaggeration to say that the underground gas storage cavern plays the role of core infrastructure in compressed air energy storage systems. It determines the amount of gas stored, system efficiency, as well as important factors such as safety and stability. Therefore, it is also one of the key technologies for developing long-duration, large-scale compressed air energy storage, and has long been a focus of the industry.

Xinyang Underground Gas Storage Cavern, 300,000 m³ “Hidden Potential Inside”

The Henan Xinyang 300MW advanced compressed air energy storage national demonstration power station is a national new energy storage pilot demonstration project, and was successfully included in the fourth batch of “First (Set) of Major Technical Equipment in the Energy Field” by the National Energy Administration. Once completed, it is expected to generate 420 million kWh annually, effectively improving the efficiency, economics, and reliability of the local power system. In the field of compressed air energy storage, it has technological pioneering significance and major demonstration value.

The head of the Xinyang project department revealed to reporters, “The underground gas storage cavern of this power station adopts unique designs such as the ‘high-efficiency self-draining system’ and the ‘breakthrough ultra-large tunnel diameter’.”

High-Efficiency Self-Draining System Shows Remarkable Effect

He further explained: “Accumulated water caused by geological conditions in underground gas storage caverns has long been one of the key technical challenges troubling the safety and construction efficiency of compressed air energy storage underground gas storage caverns. This time, the high-efficiency self-draining system, innovatively designed by technical personnel, through rational design of the longitudinal slope of the gas storage cavern and lowering the internal water level, fundamentally solved this technical problem, significantly improved the long-term safety and operational stability of the system, and provided a brand-new solution for the construction of drainage systems in gas storage caverns under complex geological conditions.”

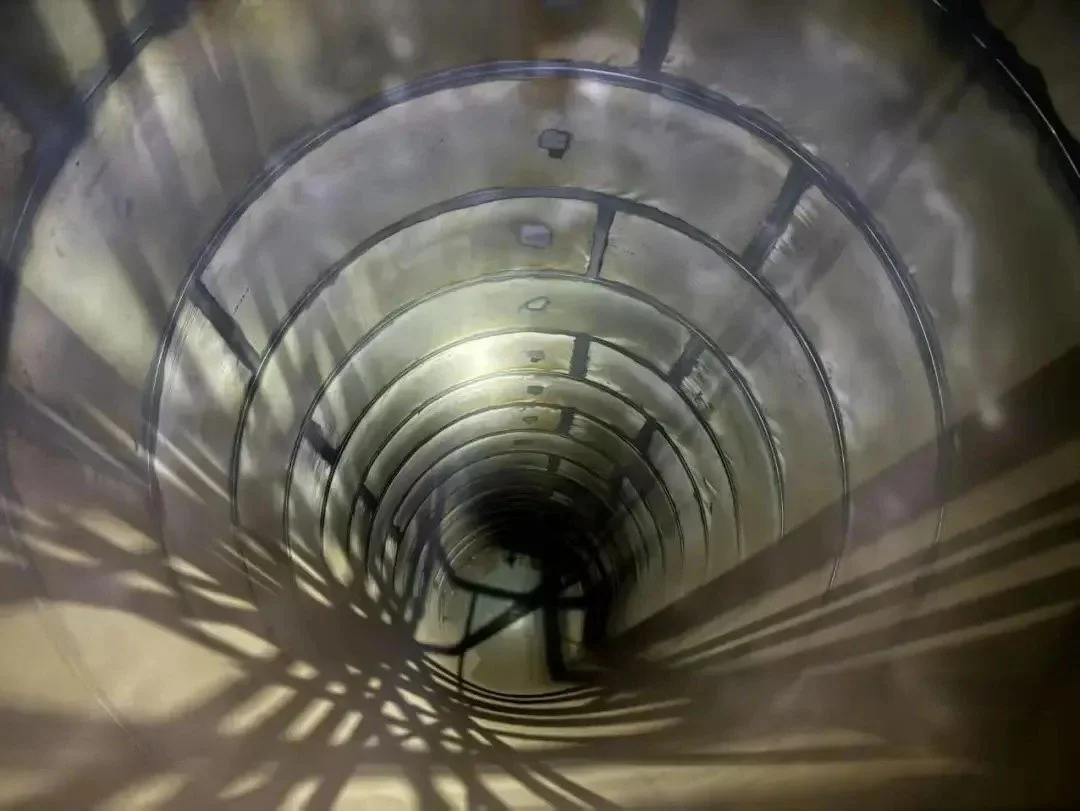

Cost Reduction and Efficiency Improvement, China’s First 15-Meter Ultra-Large Tunnel Diameter Design

Another highlight of the Xinyang project is the domestic breakthrough of adopting a 15-meter ultra-large tunnel diameter design for the first time. This innovative design increased the effective volume of the gas storage cavern to 300,000 cubic meters, expanding the scale by 300% compared with the previous largest design. While ensuring structural stability, it provided sufficient space support for a 300MW large-scale gas storage system, greatly improving unit cavern storage density and engineering economy. With a 50% increase in tunnel diameter, simple calculations show that this alone reduced costs by 200 million RMB, truly achieving the synergy of safety, efficiency, and economy.

Pioneering Horizontal Excavation Perfectly Solves Geological Problems

So what is the difference between horizontal-entry underground gas storage caverns in compressed air energy storage systems and traditional methods, and what are the advantages?

Traditional vertical-entry or inclined-shaft-entry construction has a long construction cycle and high costs, while horizontal-entry construction has relatively lower risks, lower costs compared with vertical shafts, and more convenient transportation during construction.

The technical team, for the first time in the field of compressed air, adopted horizontal-entry technology, which can extend along the strike of rock formations or stable strata, flexibly avoiding faults, and effectively solving adverse geological problems such as water-inrush zones. Compared with vertical shafts, it can more accurately select rock masses with good integrity and high compressive strength as the main cavern body, reducing construction risks caused by deep geological variations (such as soft rock interlayers, high water pressure zones). It also has obvious advantages in terms of environmental impact and economy.

Pingjiang Underground Gas Storage Cavern, the Starting Point of Underground Gas Storage Innovation

The ingenious design of the underground gas storage cavern at the Henan Xinyang 300MW advanced compressed air energy storage national demonstration power station is just a small reflection of China National Energy Technology’s in-depth cultivation of compressed air energy storage technology and engineering applications in recent years.

If we trace back this path of innovative exploration, every project shines like a pearl, strung together into a brilliant chain of underground gas storage caverns for compressed air energy storage by China National Energy Technology, China, and even the world. And to look back at the beginning, we must return to 2018…

In 2018, the founding year of China National Energy Technology, its incubator—the Institute of Engineering Thermophysics, Chinese Academy of Sciences—participated in the experimental work of the shallow-buried underground gas storage experimental cavern for compressed air energy storage in Pingjiang, Hunan, together with Central-South Design Institute of Power Construction. This was also the first domestic hard-rock shallow-buried gas storage experimental cavern for compressed air energy storage.

It broke through the limitations of traditional salt-cavern gas storage and provided important technical support for the engineering practice of shallow-buried gas storage caverns in compressed air energy storage, which was also the starting point of China’s underground gas storage cavern development for compressed air energy storage.

Unceasing Exploration, Zhangjiabei International First 100MW Project Achieves New Breakthrough

Soon after the Pingjiang project, starting from 2018, China National Energy Technology and the Institute of Engineering Thermophysics, Chinese Academy of Sciences, launched relevant research topics and project construction for the Zhangjiakou, Hebei, International first 100MW advanced compressed air energy storage national demonstration power station. Among them, the underground gas storage cavern construction was the world’s first underground artificial cavern for a 100MW-level compressed air energy storage system, and also the world’s first 100,000 m³ underground gas storage cavern.

The Zhangjiabei project is a milestone for the world’s new-type compressed air energy storage entering the 100MW-level engineering stage. It greatly advanced the industrialization and engineering application of new compressed air energy storage, adding another powerful tool for long-duration, large-scale energy storage. The power station construction received support from major projects such as the National Renewable Energy Demonstration Zone of the National Development and Reform Commission, and was included in the First (Set) of Major Technical Equipment in the National Energy Field and typical cases of green and low-carbon technology in the Beijing-Tianjin-Hebei region, with extraordinary significance.

Multiple Technical Measures to Solve Complex Geological Problems of Weak Interlayers

By adopting underground artificial caverns, the siting of compressed air energy storage becomes more flexible and can better coordinate with wind and solar power bases. However, China’s vast territory and complex geological conditions also bring various challenges to underground gas storage cavern excavation.

The basalt at the Zhangjiabei project site contains complex geology with weak interlayers, including fractured zones and densely jointed zones, which posed great challenges to construction safety and gas storage cavern stability. Technical personnel creatively adopted systematic anchor-shotcrete support, advanced anchor rods, and other measures to solve the rock mass issues, while also using advanced geological prediction and concrete replacement technologies to improve excavation safety and the stability of surrounding rock under long-term high-pressure air cycling loads. These efforts provided valuable first-hand data for constructing underground gas storage caverns for compressed air energy storage under complex geological conditions.

Unique Sealing Layer Technology Ensures Safe and Efficient Operation

For the first time at the Zhangjiabei project gas storage cavern, China National Energy Technology adopted high-strength steel, effectively solving the problems of safe and stable operation and sealing of the cavern under high air pressure during operation. At the same time, it addressed the external water pressure caused by higher water heads during operation and maintenance periods, strongly ensuring the safe and efficient operation of the underground gas storage cavern under complex geological conditions.

Tailored Drainage Technology Solutions

Just as the weather cannot be accurately predicted, geological conditions are also difficult to fully understand through preliminary surveys. In solving geological seepage and leakage problems, technical personnel, through practice, designed and summarized a professional anti-seepage and drainage solution. This scheme follows the principle of “block first, then drain; combining blocking and draining,” addressing the impact of groundwater on construction safety.

Breaking Through Soft Rock Limitations, Consolidating the Demonstration Role of the Zhongning Underground Gas Storage Cavern

In October 2023, the Datang Zhongning 100MW advanced compressed air energy storage national demonstration power station began construction. It is a project supported by the special fund of the National Development and Reform Commission and has demonstration and leading roles in scientific research innovation, equipment manufacturing, and engineering construction. Once completed, it is expected to generate 120 million kWh annually, providing important support for Ningxia to build a national new energy comprehensive demonstration zone.

Building the First Domestic Fully Artificial Cavern Underground Gas Storage in Soft Rock

Northwest China is the concentration area of the country’s wind and solar energy. The “West-to-East Power Transmission” is a major national energy strategy. Therefore, long-duration large-scale energy storage in the western region has become a focus of industry attention. Overcoming the limitations of soft rock geology in the western region can greatly unleash the potential of new-type compressed air energy storage in long-duration large-scale energy storage, which has great significance for both the industry and national strategic development.

Traditional gas storage cavern construction mostly chooses special geology such as salt rock or hard rock, which severely restricts the siting range of energy storage power stations. Through multiple innovative designs, the Datang Zhongning project overcame this severe limitation on the applicability of compressed air energy storage and built the first fully artificial cavern underground gas storage in soft rock strata in China.

First Domestic Ring-Shaped Gas Storage Cavern Structural Design

In the Zhongning project, technical personnel for the first time innovatively adopted a ring-shaped underground cavern structure. Through a closed-loop design, the surrounding rock stress distribution efficiency was significantly improved, achieving a technical breakthrough of stably constructing large-volume gas storage space in soft rock, greatly improving the utilization rate of underground space. This provided more possibilities for flexible siting of energy storage power stations in regions with soft rock distribution in China.

Unique Entry and Sealing Designs

In the Datang Zhongning project, technical personnel changed the traditional vertical shaft entry method, cleverly combining vertical and inclined shafts, effectively improving construction efficiency, making ventilation and drainage more convenient, while reducing interference in processes such as muck removal and steel lining assembly, thereby improving construction efficiency and results.

In terms of sealing layer design, considering the deformation-prone characteristics of soft rock strata, researchers adopted a composite design: using flexible materials to cope with deformation problems while also using rigid materials to provide stable support, ensuring the safe storage of high-pressure air at a depth of 150 meters, as well as the system’s sealing and safety.

First Multi-Ring Array Design, Yanshan Project Construction Further Upgraded

The Jiangxi Yanshan 300MW advanced compressed air energy storage national demonstration power station is a key national project in new energy storage and the energy field, included in the “New Energy Storage Pilot Demonstration Project List” and the fourth batch of “First (Set) of Major Technical Equipment in the Energy Field.”

From Single-Ring to Multi-Ring, Releasing Infinite Possibilities for Compressed Air Energy Storage

Building upon the “ring array” design of the underground gas storage cavern in the Datang Zhongning project, the Jiangxi Yanshan project achieved new breakthroughs and upgrades, for the first time adopting a “multi-ring array” design.

While ensuring the stability of the gas storage cavern, this design allows multiple gas storage caverns to operate independently, with flexible staged commissioning, calmly coping with various complex geological conditions. At the same time, it improves project construction and operation efficiency, providing sufficient technical support for the application of compressed air energy storage in more complex and diverse geological conditions.

First Application of Digital Twin Technology in Compressed Air Energy Storage Underground Gas Storage Caverns

Driven by the growing demand for “digital-intelligent” management of compressed air energy storage power stations, in 2024, China National Energy Technology took the lead in applying a “large-scale energy storage and monitoring automated management system design” in domestic compressed air energy storage underground gas storage caverns, in order to enhance management refinement and intelligence, and continuously improve the management level of power stations.

Multiple Major Projects Forge Strong Underground Gas Storage Cavern Construction Capability

We can see that from its establishment in 2018, China National Energy Technology has walked alongside the country’s first shallow-buried underground gas storage experimental cavern for compressed air energy storage—the Pingjiang storage cavern.

After continuous optimization through multiple advanced compressed air energy storage power stations, including Zhangjiabei 100MW, Datang Zhongning 100MW, Henan Xinyang 300MW, and Jiangxi Yanshan 300MW, China National Energy Technology has summarized a complete set of solutions for large-scale underground gas storage caverns under different regional and geological conditions. Beyond its outstanding advantages in compressed air energy storage system R&D, core equipment manufacturing, and system integration, it has also mastered the core competitiveness of underground gas storage caverns, laying a solid foundation for continuously growing stronger in the compressed air energy storage industry in the future.

Innovation Never Stops. China National Energy Technology General Manager Ji Lü stated to reporters that compressed air energy storage is a systematic project, and every part requires meticulous polishing and continuous iteration and upgrading. In the future, the company will continue to strengthen research investment in underground gas storage caverns, actively participate in the formulation of national and industry standards, and provide valuable technical and engineering services for compressed air energy storage and other related fields.