On January 8, 2026, a 500MWh standalone Battery Energy Storage System(BESS) project located at Maritsa East 3 in Bulgaria was officially commissioned. The project was the jointly developed by BYD Energy Storage and ContourGlobal under their strategic collaboration which is one of the largest standalone energy storage projects in East Europe.

Tianneng Signs a 1GWh Project in Malaysia, Build a benchmark for Integrated “Solar- Storage- Computing”Solutions

Recently, Tianneng Group signed a strategic agreement with NASDAQ-listed company VCIG Group. The two parties will build a 1GWh AIDC solar energy storage power station in Malacca, Malaysia. The project aims to address the high-energy-consumption challenge of AIDC and will be developed under an “EPC+F” model.

Annual Power Cost Savings Exceed RMB 60 Million ! Great Power’s 107MW/428MWh Hydropower-based Aluminium User-side Energy Storage Project is Commissioned

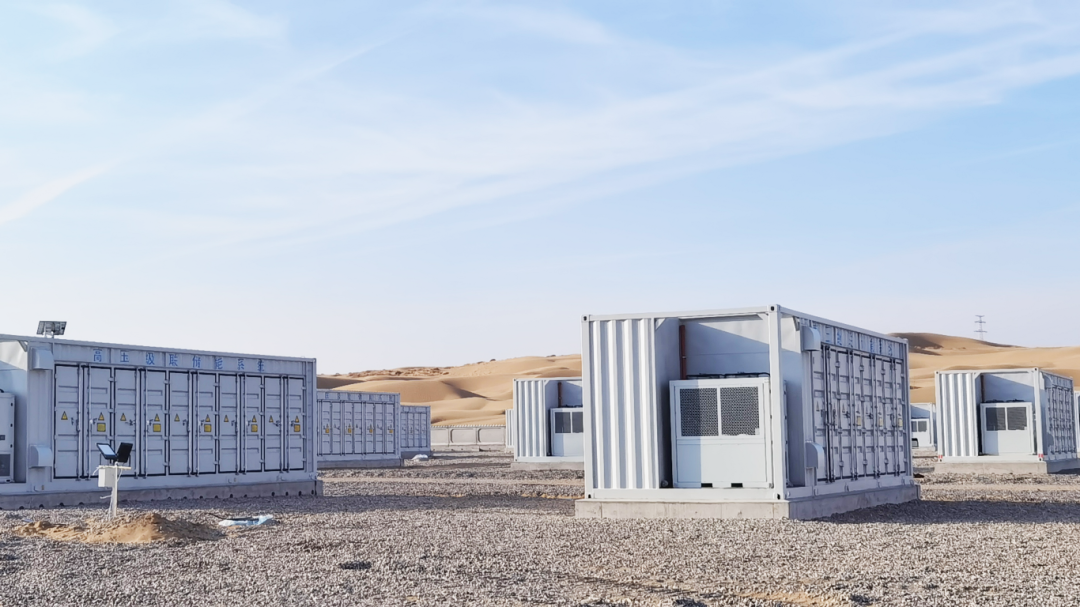

CORNEX Secures a 6GWh Energy Storage Order in Egypt, Successfully Expanding Into the North African Market

On January 16th, Cornex New Energy signed a strategic cooperation agreement with Egypt-based partners WeaCan and Kemet.

The agreement was signed by Dai Deming, chairman of Cornex New Energy and Ahmed Salaheldin Abdelwahab Elabd, Chiarman of the Board of Kemet. The signing ceremony was witnessed by Moustafa Kamal Esmat Mahmoud, minister of Egypt’s Ministry of Electricity and Renewable Energy, along with other government officials and senior executives from relevent enterprises.

100MW/200MWh! Sineng Electric Supports Commissioning of Phase I of Nanlang Energy Storage Power Station

The Phase I 100MW/200MWh Nanlang energy storage power station, supplied by Sineng Electric, has now been successfully commissioned and put into operation. As the first large-scale standalone energy storage project on the grid side to be completed and commissioned in Zhongshan, China, the facility not only injects enhanced flexibility into the regional power grid, but establishes efficient and reliable revenue mechanism through an innovative frequency regulation service model.

500MW/200MWh! JD Energy’s First GWh-Level Project Successfully Grid-Connected

In December 2025, the 500MW/2000MWh energy storage project was successfully grid-connected in Dengkou, Inner Mongolia. The energy storage station, standing proudly under the winter sun, is the first GWh-level project delivered by JD Energy. It not only set a new record for the scale of a single project but marked a significant milestone in the company’s development with its outstanding construction achievements.

Sungrow’s First Energy Storage Plant in the Middle East Launched,with an Annual Capacity of 10 GWh

Egypt has taken a major step toward accelerating its clean energy transition, as Chinese energy storage leader Sungrow and Norwegian renewable developer Scatec partner with the Egyptian government to deliver large-scale solar+storage projects and establish the Middle East’s first battery energy storage manufacturing base, with a planned annual capacity of 10 GWh.

4.8 GWh Installed: Beijing KeRui Supports the Grid Connection of Two Major Grid-Side Energy Storage Projects in Inner Mongolia, Chi

China Mingyang Longyuan’s First 100MW/400MWh High-Voltage Cascade Independent Energy Storage Project Achieves Full-Capacity Grid Connection

Mingyang Longyuan has built a major milestone in China’s energy storage sector with the successful full-capacity grid connection of its first 100MW/400MWh high-voltage cascade independent energy storage project in Ordos, Inner Mongolia. The project’s commissioning highlights the company’s technological strength in large-scale, high-efficiency, and highly reliable energy storage solutions, while reinforcing the critical role of advanced storage systems in supporting grid stability and renewable energy integration.

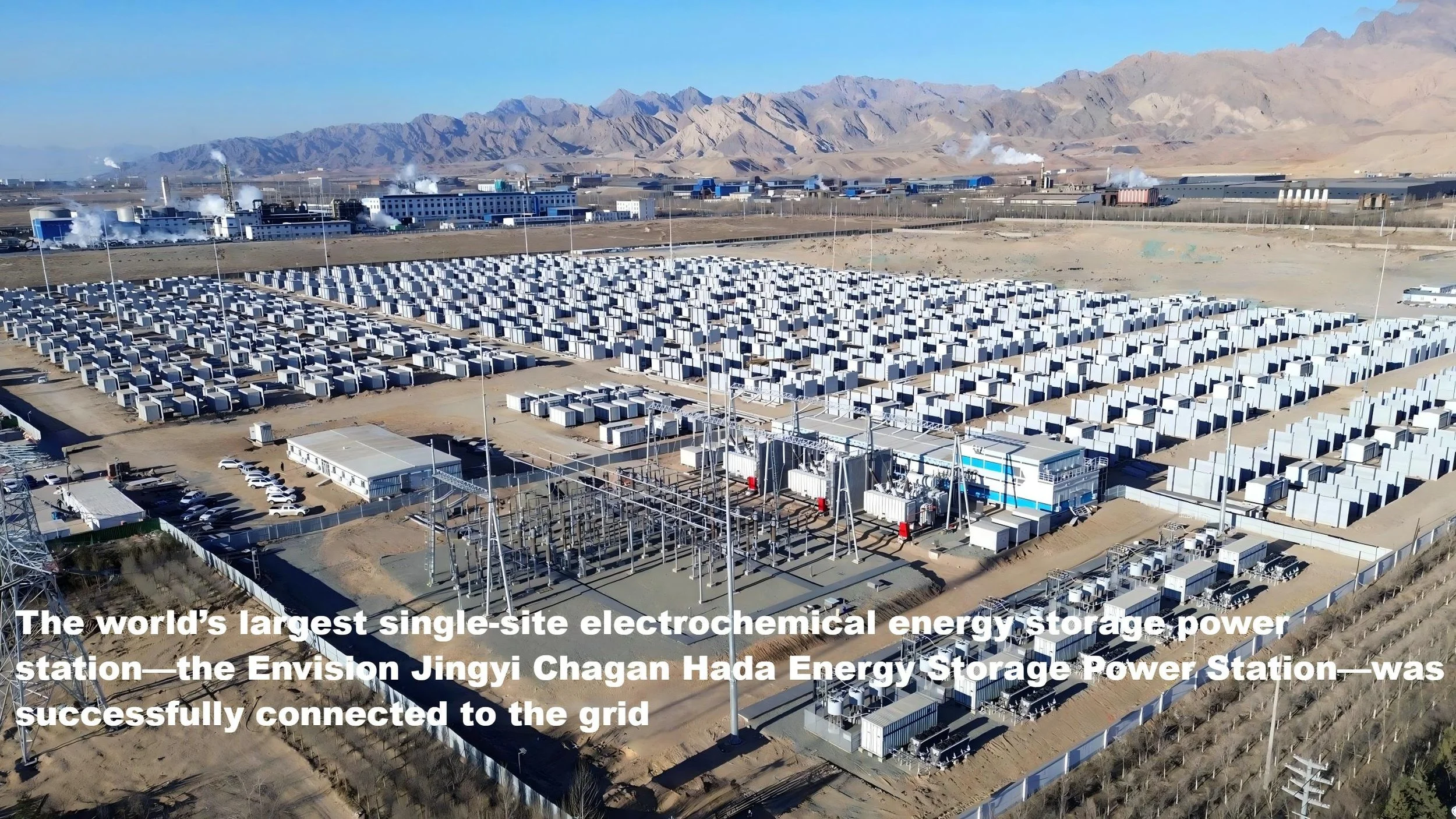

12.8 GWh Energy Storage Cluster Connected to the Grid AI-Powered Energy Storage Reshapes the Future of New Power Systems

The world’s largest single-site electrochemical energy storage power station—the Envision Jingyi Chagan Hada Energy Storage Power Station—was successfully connected to the grid, completing a 12.8 GWh AI-powered energy storage cluster in Inner Mongolia. The project sets new global benchmarks for scale, grid-connection speed, and system reliability, while demonstrating advanced grid-forming capabilities that enable rapid commissioning, deep grid interaction, and large-scale renewable integration.

Germany Roundup: 500MW BESS and Data Centre Transaction, Seven-Year Toll and 370MW Pipeline Secured

Source: Energy Storage News

The BESS with which ju:niz Energy will enter into a toll with Next Kraftwerke. Image: ju:niz Energy

A trio of German grid-scale BESS news items, with Next Kraftwerke and ju:niz Energy agreeing a seven-year toll, Alpiq announcing a 370MW pipeline, and WBS Power selling the country’s largest solar-plus-storage project and planning a data centre on the same site.

Germany has this year become a hotbed of battery energy storage system (BESS) project announcements and deal-making, driven by its substantial revenue opportunities as Europe’s largest electricity market and a looming August 2029 deadline for getting projects operational to avoid charge-discharge grid fees. See all recent coverage here.

WBS Power sells solar-plus-storage project, plans data centre

Developer WBS Power has sold the 150MW solar, 500MW/2,000MWh BESS Project Jupiter in Brandenburg, Germany, to investor Prime Capital.

WBS acquired the site for the clean energy project in 2022, and the project will require €500 million (US$583 million), with construction expected in late 2026/early 2027. Both technologies will share a 380kV grid connection in the area of TSO 50Hertz. The acquisition is subject to Project Jupiter reaching ready-to-build (RTB) status.

The transaction also establishes a joint venture to co-locate a hyperscale data centre of up to 500MW in power demand in the same area.

WBS Power said there is growing demand for data centres in Germany, which are highly energy-intensive and benefit significantly from direct access to renewable power and grid stability.

“By integrating Germany’s largest co-located BESS and Solar PV project with a hyperscale data center, we are creating a unique platform that supports both the energy transition and digital transformation,” said Maciej Marcjanik, CEO of WBS Power Group.

Alpiq secures 370MW Germany pipeline

Switzerland-based energy firm Alpiq has expanded in Germany with a 370MW BESS pipeline the company has ‘secured’, in partnership with developer SPP Development. The projects in Brandenburg and Saxony-Anhalt are expected to reach RTB status in 2026.

Lukas Gresnigt, Head International and member of the Executive Board of Alpiq said that Germany is a competitive and complex market for BESS, with many projects are queuing for grid access and permits, and the partnership combined Alpiq’s financial strength and SPP’s local expertise.

Last week, Energy-Storage.news reported on Alpiq entering into a long-term toll for a BESS in Germany owned and operated by Eco Stor. Alpiq has acquired projects in France and Finland, where it recently commissioned a 30MW/36MW project.

Shell and EQT companies agree Germany BESS toll

VPP operator Next Kraftwerke, acquired by Shell in 2021, has concluded a Germany BESS toll with BESS platform ju:niz Energy, acquired by investor EQT in 2024.

The seven-year toll is for a 20MW/40MWh project in Vöhringen, Bavaria, and Next said it is one of the first operational contracts of its kind in Germany, live since 1 November.

Next Kraftwerke will pay ju:niz Energy a fixed monthly fee per installed MW for the use of the BESS capacity. The model offers stable revenues for the operator (ju:niz) and flexibility for the optimiser (Next Kraftwerke). The toll is 80% fixed remuneration and 20% merchant, Next said.

(By Cameron Murray)

CENSA Upcoming Events:

Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Dec 31, 2025.

Cache Power Plans ‘Canada’s First’ Commercial-Scale Compressed Air Energy Storage Facility

Source: Energy Storage News

The facility will be constructed in two phases and located next to the Marguerite Lake substation to enhance efficiency and facilitate grid integration. Image: EllisDon

Compressed air energy storage (CAES) developer Cache Power is partnering with construction company EllisDon to deliver a CAES facility in Northeast Alberta, Canada.

The facility will be constructed in two phases and located next to the Marguerite Lake substation to enhance efficiency and facilitate grid integration.

Cache Power does not have any information on its website, but appears to be a special purpose vehicle (SPV) for Federation Engineering.

On Federation’s website, the company clarifies that the Marguerite Lake facility will have a 250MW load capacity and 640MW generation capacity. Energy storage capacity or planned duration were not referred to in publicly available materials.

The companies assert that the technology will be essential in stabilising Alberta’s grid and supporting both provincial and national efforts toward a net-zero electricity future. The project has secured all key regulatory approvals, with early construction scheduled to start soon.

CAES technology operates by pressurising and directing air into a storage medium to load the system. When discharging, the stored air is released through a heating system to expand, driving a turbine generator.

Notably, the companies claim the project will be the first commercial scale CAES facility in Canada.

Ontario-headquartered Hydrostor is known for its advanced compressed air energy storage (A-CAES) projects.

A-CAES operates similarly to traditional CAES but captures heat from the compressor and passes it through heat exchangers to store in pressurised water. This water is kept in a reservoir and then released into a cavern to displace air during discharging, a process known as hydrostatic compensation.

In conventional CAES, less than 50% of the energy can typically be recovered. The thermal energy produced during compression is often wasted, and the power output varies depending on the residual underground air pressure.

Hydrostor has two small operational projects in Canada, one a pilot and the other a commercial demonstrator, with the larger one being a 2.2MW/10MWh commercial system in Goderich, Ontario.

Hydrostor noted the Goderich Energy Storage Centre as the world’s first commercially contracted A-CAES facility. In addition to its role as technology provider, the A-CAES company is also developing large-scale projects around the world, including its 1.6GWh Silver City project in New South Wales, Australia, and 4GWh Willow Rock project in California, US. The company has secured some funding and offtake agreements for both, including a recent renegotiation of contracts for Willow Rock (ESN Premium article).

It has also proposed a 500MW/8,000MWh project in Ontario (ESN Premium), adjacent to Ontario Power Generation’s Lennox Generating Station in Greater Napanee.

Speaking with Energy-Storage.news, a representative from Federation clarified that the distinction between the CAES system titles for itself and Hydrostor came down to scale and usage.

Cache Power’s facility can store up to 48 hours of energy by compressing air with excess grid electricity and sequestering it in underground salt caverns formed through solution mining.

It can also blend up to 75% hydrogen with natural gas, with a future plan for complete hydrogen utilisation, aligning with Canada’s net-zero ambitions.

Power plant equipment supplier Babcock & Wilcox are collaborating on engineering the possible hydrogen facility expansion, employing the company’s BrightLoop technology.

Babcock & Wilcox claim that BrightLoop can produce hydrogen while isolating carbon dioxide for capture and storage.

Additionally, Cache Power states it will deliver economic and social advantages to the local community and Indigenous Partners. Cold Lake First Nations has actively engaged in the project’s development and is anticipated to collaborate as a partner with Cache Power in both the project and its operations.

Update: Jordan Costley, Director of Sustainability Projects at Federation Engineering, and President of Cache Power has clarified that the project will be 30.72GWh. Costley also added about CAES energy recovery:

“(The 50% recovery statistic) may have been true for the original D-CAES projects such as Huntorf (Germany 1978) and McIntosh (USA 1991) but our project is utilizing the latest D-CAES technology from Siemens Energy.“

“Today’s compression technology utilising multi-stage integrally geared and intercooled compressors is very efficient resulting in the heat of compression being low grade not valuable for thermal energy storage and reuse in the expansion process. The expander trains also include 90% effective dual-reheat recuperators again significantly increasing the overall efficiency. The technology we are utilizing is not “conventional CAES” as defined by Huntorf and McIntosh.

(By April Bonner)

CENSA Upcoming Events:

Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Dec 31, 2025.

4GW/5.12GWh Malaysia Solar-Plus-Storage Hub Receives World Bank Funding

Source: PV Tech

The agreement was signed this week, in the presence of the Queen of Malaysia (pictured). Image: IFC

The World Bank will invest in a huge 4GW, 5.12GWh solar-plus-storage complex in Malaysia, which will form part of a pan-Southeast Asian power grid initiative.

The Southern Johor Renewable Energy Corridor (SJREC) will be a roughly 2,000sqKm area dedicated to solar PV and energy storage capacity. The US$6 billion project is backed by the World Bank’s private investment arm, the Iternational Finance Corporation (IFC), alongside the state investment firm of Johor, Permodalan Darul Ta’zim (PDT), and Ditrolic Energy, a Malaysian integrated energy company.

The project is part of a number of larger schemes, chiefly the ASEAN Power Grid Initiative, a plan to integrate power grids and energy supply across Southeast Asian nations. In this vein, the SJREC will be part of the Johor–Singapore Special Economic Zone (JS-SEZ) “masterplan”, able to transmit clean energy to Singapore, which sits on Johor’s southern border.

As a densely populated city state, Singapore relies heavily on energy imports and has made significant plans for cross-border renewables transmission, perhaps most notably the mammoth AA PowerLink project in Northern Australia, which aims to deploy almost 20GW of solar capacity when fully operational and supply power to Singapore via undersea cables.

The site is also part of the Johor Green Development Policy 2030, which the state government introduced to expand its green industries and renewable energy developments.

“As the state agency entrusted to formulate the Johor Green Development Policy 2030, PDT is proud to witness our strategic framework transition into tangible reality today,” said Dato’ Ramlee bin A Rahman, president and group chief executive of Permodalan Darul Ta’zim.

“The Southern Johor Renewable Energy Corridor was conceived as the cornerstone of this policy, specifically Strategy one, to unlock the immense solar potential of the Kota Tinggi and Mersing districts.”

Tham Chee Aun, CEO of Ditrolic Energy, said the SJREC hub would “Anchor Johor’s clean energy export potential and provide a foundation for industries seeking renewable, low-cost power in the region.”

In an announcement, the IFC said the project would supply renewable energy to “local and multinational corporations, including hyperscale data centre operators, manufacturers, and other businesses in Johor”.

Renewables development is a major driver for meeting data centre power demand, primarily because of the affordability of solar projects and solar energy and the stability offered by coupling the technology with energy storage. In its most recent report, the International Energy Agency (IEA) said the world would become “thirsty for energy” in the coming years and that data centres were an “Important driver” of growing power demand.

(By Will Norman)

CENSA Upcoming Events:

Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

200MW/800MWh! China's Largest Semi-Solid-State Energy Storage Project Connected to the Grid

Source: CCTV News

According to a report by CCTV News on December 1, China Green Development Group announced that a 200MW/800MWh semi-solid-state battery energy storage project located in Wuhai, Inner Mongolia, has been successfully connected to the grid. The project not only sets a new record for the installed capacity of grid-connected semi-solid-state lithium battery energy storage in China, but also marks a crucial step for China's semi-solid-state energy storage technology from pilot demonstration to large-scale commercial operation.

As a major new energy hub in northwest China, Wuhai city in the Inner Mongolia Autonomous Region, has leveraged its abundant wind and solar resources to consistently advance integrated development of “source-grid-load-storage” in recent years. This newly grid-connected energy storage facility serves as a core infrastructure project for enhancing local renewable energy consumption. Covering an area of about 100 mu (about 6.67 hectares), the project is equipped with 160 energy storage battery containers and 40 converter and booster integrated units.

Semi-Solid-State Lithium Battery Energy Storage Project Successfully Connected to the Grid in Wuhai, Inner Mongolia

Qin Lei, Project Manager of Wuhai Energy Storage Project, Inner Mongolia Branch, China Green Development Group:

“This massive ‘power bank’ utilizes domestically-developed semi-solid-state lithium iron phosphate battery technology, which offers significant advantages in safety performance, energy density, and cycle life compared with conventional liquid lithium iron phosphate batteries.”

With the rapid upgrade of the new energy industry, energy storage - essential for grid peak regulation, frequency modulation, and improving renewable energy utilization - is entering a phase of large-scale expansion. Semi-solid-state lithium battery technology represents a key direction for the future development of power and storage batteries. Using a hybrid solid-liquid electrolyte, semi-solid-state batteries retain the high ionic conductivity of liquid systems while achieving a cycle life exceeding 12,000 cycles, which greatly reduces lifecycle operational costs. In addition, they can effectively suppress lithium dendrite growth, further enhancing safety.

Semi-Solid-State Lithium Battery Energy Storage Project Successfully Connected to the Grid in Wuhai, Inner Mongolia

Liu Xiaofei, Assistant General Manager, Inner Mongolia Branch, China Green Development Group:

“Once fully operational, the project will feature a peak-shaving and frequency-regulating capability of 200MW/800MWh, providing 189,000 MWh of clean electricity to the grid annually. It enables flexible scheduling - storing energy during the day and supporting peak loads at night - significantly enhancing power system stability. It will also ensure that local green electricity can be fully delivered, stably transmitted, and efficiently utilized, solving key bottlenecks in regional renewable energy consumption.”

Semi-Solid-State Lithium Battery Energy Storage Project Successfully Connected to the Grid in Wuhai, Inner Mongolia

In recent years, semi-solid-state lithium batteries - offering both high safety and strong economic performance - have become a core direction of technological evolution in the energy storage sector. Previously, China's largest grid-connected semi-solid-state storage project had a capacity of 100MW/200MWh. The Wuhai project doubles that scale, demonstrating that China is now at the global forefront of large-scale applications of semi-solid-state energy storage technology.

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

China's Largest Grid-Side Lead-Carbon Energy Storage Power Station Goes Online

Source: Science and Technology Daily

At 19:18 on November 26, the battery cabin of the Diannong No.1 Energy Storage Station - part of the 200 MW / 400 MWh shared energy storage project by Ningxia Jiyang Green Storage - was successfully energized for the first time, marking the successful grid connection and commissioning of China's largest grid-side lead-carbon energy storage power station.

The Jiyang Green Storage 200 MW / 400 MWh shared energy storage project was invested and constructed by Ningxia Jiyang Green Storage Integrated Energy Services Co., Ltd. Covering an area of 55.4 mu (≈ 3.7 hectares) with a total investment of 620 million yuan, the project sets new records for the largest scale and highest power among grid-side lead-carbon energy storage stations. It is located in the core energy corridor of Xixia District, Yinchuan, and is equipped with 80 customized lead-carbon energy storage integrated cabins.

The system boasts a cycle life of over 6,000 cycles - 3 times that of traditional lead-acid batteries and 1.5 times that of lithium batteries - with a full life-cycle cost 40% lower than lithium batteries, making it the most cost-effective large-scale energy storage solution in China.

The State Grid Yinchuan Electric Power Company comprehensively tracked the project's construction progress, coordinated every step, and organized a professional technical team of dozens of staff from power dispatch, operation and maintenance, marketing, and information communications to provide grid connection services. The power dispatch control center assigned dedicated personnel for over 300 days of full-process monitoring. Under the overall deployment of State Grid Ningxia Electric Power Co., Ltd., both State Grid Yinchuan Electric Power Company and Ningxia Jiyang Green Storage actively coordinated to ensure the smooth grid connection of the Diannong No.1 Energy Storage Station.

“A successful grid connection of this project helps accelerate the integrated development of Yinchuan's energy storage industry and supporting clean energy sectors, enhances the grid's flexible regulation capability, increases renewable energy absorption, and eases peak electricity supply pressure. It also serves as an important demonstration for the integration of ‘generation-grid-load-storage’ and multi-energy complementarity,” said a relevant official from State Grid Yinchuan Electric Power Company.

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

73 Billion Yuan Investment! 4.8 GWh of Energy Storage! SPIC Launches 19.44 GW “Desert-Gobi-Wasteland” Mega Project

Source: CCTV News

On November 27, according to the State Power Investment Corporation (SPIC), construction has officially begun in Xining, Qinghai Province on China's largest power supply project with the highest share of new energy - the Qinghai Hainan Clean Energy Delivery Base Project, part of the national “Desert-Gobi-Wasteland” mega base initiative.

“Desert-Gobi-Wasteland” refers to vast desert and semi-arid regions, which are rich in wind and solar resources. The project in Qinghai's Hainan Prefecture represents a total investment of nearly 73 billion yuan, with a planned installed capacity of 19.44 GW. New energy accounts for 86.4% of the total, including 9.6 GW of solar PV, 6 GW of wind power, 2.64 GW of supporting coal-fired power, and 1.2 GW/4-hour of electrochemical energy storage (4.8 GWh). The project will transmit electricity directly to Guangdong via a ±800 kV ultra-high-voltage DC transmission line with a capacity of 8 GW.

Once completed, the project will generate an average of 36,000 GWh of electricity annually, equivalent to saving about 10 million tons of standard coal and reducing carbon emissions by roughly 23.5 million tons. It will deliver 36,000 GWh of power annually to the Guangdong-Hong Kong-Macao Greater Bay Area, playing a major strategic role in optimizing China's energy mix and supporting high-quality development in the eastern region.

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

3,200 MWh New Energy Storage Projects Reach Key Milestones

Source: CNESA

Recently, multiple new energy storage projects across China have reached important milestones. In Shandong, Xinjiang, Hebei, Qinghai, and Inner Mongolia, several 100-MW-level projects have either started construction or successfully connected to the grid. Technologies involved include flywheel storage, lithium iron phosphate (LFP) batteries, hydrogen storage, and more - together painting a rapidly emerging panorama of diversified and large-scale storage development.

Breakthrough in Grid Frequency Regulation: World's First 100-MW

Flywheel Storage Demonstration Project Commissioned

The world's first 100-MW independent flywheel frequency-regulation demonstration plant - the Boding Energy 100 MW Vacuum Magnetic Suspension Flywheel Independent Frequency Regulation Project (Phase I) - has officially been commissioned in Rushan, Weihai, Shandong. Sungrow's energy storage PCS integrated system introduced multiple hardware and software innovations tailored for flywheel storage, achieving key breakthroughs in response speed and operational reliability, and setting a new benchmark for frequency-regulation applications.

Phase I of the Rushan Bodin flywheel project was grid-connected in July, and Phase II has already been included in Shandong's 2025 New Energy Storage Demonstration Program. The project's successful commissioning verifies Sungrow's PCS stability and rapid system response in flywheel-based frequency regulation, enhances overall operational efficiency, and lays a strong foundation for large-scale deployment of flywheel energy storage in grid applications.

CGN's 200 MW / 800 MWh Independent Energy Storage Project in

Lop County, Xinjiang Breaks Ground

On November 16, CGN (China General Nuclear Power Group Co., Ltd.)'s 200 MW / 800 MWh independent energy storage project in Lop County, Hotan Prefecture, Xinjiang officially started construction. Located about 20 km from Luopu County, the project is invested in and developed by CGN New Energy Lop Co., Ltd., and constructed by China Energy Engineering Xinjiang Electric Power Construction Co., Ltd.. The project will build a centralized electrochemical storage station with a planned total capacity of 200 MW / 800 MWh.

Hebei Zhuozhou 200 MW / 800 MWh Independent Energy Storage

Project Starts Construction

On November 18, construction officially began on the 200 MW / 800 MWh independent energy storage station in Zhuozhou, Hebei. As a key pilot project supported by Hebei Province, it carries a total investment of over 1 billion RMB. Jointly developed by DURIA TECH, CORUN, CALB, and Guoxia Technology, the project establishes a full-chain closed-loop system from upstream materials to mid-stream equipment and downstream operations - advancing integrated “project development + supply chain security + full-cycle services.”

The project adopts a hybrid “lithium iron phosphate + nickel-metal hydride” storage technology route. Once completed, it will significantly enhance peak-shaving and frequency-regulation capability for the Beijing-Tianjin-Hebei grid, supporting efficient renewable-energy consumption and improving grid safety and stability.

150 MW / 600 MWh: SPIC Qinghai Haixi Grid-Side Storage Project

Breaks Ground

On November 13, Huanghe Hydropower Development Co., Ltd. Under the SPIC (State Power Investment Corporation Ltd.) held a groundbreaking ceremony for the Qinghai Haixi Tuosu grid-side electrochemical storage project at the Yixuan PV power station. The project is part of the supporting storage facilities for the first phase of the company's 2.2 GW multi-energy complementary project in Delingha. With a planned capacity of 150 MW / 600 MWh, the station will significantly enhance the grid's peak-shaving ability and its capability to absorb PV and other renewable generation.

The project includes a 100 MW / 400 MWh centralized storage system and a 50 MW / 200 MWh high-voltage cascaded storage system, both designed to provide reliable power support during peak demand periods.

300 MW / 600 MWh: Xinjiang's First Immersed Energy Storage

System Commissioned

On November 9, the energy storage project invested by Xinjiang Weilan New Energy Technology Development Co., Ltd. - the first large-scale electrochemical energy storage station in the Xinjiang Production and Construction Corps (XPCC) and the first immersed energy storage system in Xinjiang - successfully completed all equipment commissioning and was energized and put into operation.

The project turns “technological firsts” into “industry benchmarks,” adopting a mature immersed-system design paired with high-safety LFP batteries. As Xinjiang's first immersed-system energy storage project, it can control battery operating temperature differences within ≤2 °C. Combined with its large 300 MW / 600 MWh configuration, the project fills the technical gap for large-scale electrochemical storage within the XPCC.

100 MW / 400 MWh: Independent Grid-Side Storage Demonstration

Project in Huade, Ulaanqab (Inner Mongolia) Successfully Connected

On November 13, the electrochemical portion of the Huade County grid-side independent energy storage demonstration project in Ulaanqab, Inner Mongolia, was successfully connected to the grid. The project includes a total planned capacity of 100 MW / 400 MWh, adopting a hybrid “electrochemical + hydrogen storage” configuration:

Electrochemical storage: 90 MW / 360 MWh, providing second-level frequency regulation and short-term peak-shaving;

Hydrogen storage: 10 MW / 40 MWh, serving long-duration storage (scheduled for completion and grid connection in 2026).

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

World's Highest-Altitude Operating Wind Power Project Now Connected to the Grid

Source: China Electric Power News

On November 17, against the backdrop of the majestic Yarlha Shampo Snow Mountain, the China Huadian Corporation’s Wind Power Project in Qonggyai County - whose highest turbine installation point sits at an altitude of 5,370 meters - was officially connected to the grid. The project is not only the largest single-unit-capacity wind power project in the Tibet Autonomous Region, but also the world's highest-altitude operating wind power project, injecting new momentum into green and low-carbon development on the Tibetan Plateau.

Located in Zhongdui Village, Qonggyai County, Shannan City, the Huadian Qonggyai Wind Power Project has a total installed capacity of 60 MW. It is equipped with eleven 5.0 MW turbines and one 6.25 MW turbine, along with a supporting 12 MW/48 MWh grid-forming energy storage system. Once in operation, the project is expected to supply clean electricity sufficient for about 120,000 households annually, equivalent to reducing carbon dioxide emissions by 128,700 tons per year.

Constructing a wind farm at an altitude of 5,370 meters requires overcoming conventional engineering limitations. Facing extreme conditions - oxygen levels at only 57% of those in lowland areas, day-night temperature variation exceeding 20°C, and cumulative road elevation gain of 1,670 meters - the project team tackled challenges with innovative practices:

they planned logistics routes in advance, optimized the allocation of equipment and personnel, and ensured efficient material transportation; they improved concrete mix designs and pioneered a “film + quilt + tarpaulin” layered insulation method, combined with an intelligent temperature-control curing system, to ensure concrete strength and durability in low-temperature environments. These solutions enabled continuous one-time pouring of large-volume concrete under high-altitude, low-oxygen conditions, providing replicable technical experience for ultra-high-altitude wind power construction worldwide. The team also innovated construction methods by applying single-blade hoisting technology for the first time ever at altitudes above 5,000 meters - saving about 66% of the working area compared with traditional whole-rotor hoisting and increasing the upper limit of operable wind speed to 10 m/s - laying a solid foundation for the project's high-quality commissioning.

Throughout construction, the company fully upheld the principles of being “system-friendly, eco-friendly, and community-friendly.” The project incorporates a “equipment selection + energy storage + intelligent control” technical system with a grid-forming storage facility to effectively smooth wind power fluctuations and enhance grid reliability. It strictly followed the four-step method of “lifting, preserving, nurturing, restoring” for high-altitude meadow protection and adopted high-performance substrate ecological spraying technology, restoring a total of 360,000 square meters of vegetation and installing 120,000 square meters of protective mesh, ensuring coordinated progress between engineering development and ecological conservation.

Meanwhile, through land leasing, local employment, construction participation, and skills training, the project directly increased local residents' income by more than 3.6 million yuan and boosted local industries by over 11 million yuan, ensuring that the benefits of clean energy development are shared by people of all ethnic groups in the region.

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

CLOU Electronics’ Indonesia Energy Storage Base Set for 2026 Commissioning, Targets 3GWh Capacity

Source: CNESA

On November 6, CLOU Electronics announced key progress in its global manufacturing expansion, revealing that its energy storage production base in Indonesia is currently under construction and scheduled to commence operation in 2026. The facility has an initial planned capacity of 3GWh per year, with flexibility for future expansion based on market demand and business growth.

CLOU Electronics is a national high-tech enterprise in China with a number of national and provincial technical centers and laboratories. Focusing on two major fields including new electrochemical energy storage and new power system, CLOU Electronics has long accumulated deep technological expertise and extensive project experience in the energy storage sector. The company has achieved full in-house research, development, and manufacturing capabilities for core system components - including PCS, BMS, EMS, DC/DC converters, and O&MS platforms - enabling it to deliver comprehensive integrated energy storage solutions.

The Indonesia Energy Storage Base marks a strategic milestone in CLOU Electronics’ globalization roadmap. The site will focus on research, development, and large-scale production of key products such as lithium-ion battery energy storage systems and energy storage inverters (PCS). It will also include intelligent production lines, R&D and testing centers, and warehousing and logistics facilities.

Leveraging Indonesia’s abundant nickel and cobalt resources, the project aims to establish a fully integrated overseas industrial ecosystem of “resources-R&D-manufacturing-application.” This approach is expected to reduce supply chain costs and mitigate geopolitical risks, while enhancing production efficiency and responsiveness to regional demand.

As one of the world’s fastest-growing energy storage markets, Southeast Asia has seen rapid expansion driven by the rise of renewable energy installations and urgent power grid upgrades. The commissioning of CLOU’s Indonesian base will enable the company to provide localized products and solutions for utility-scale, industrial, commercial, and off-grid energy storage applications across ASEAN countries, the Middle East, and beyond.

CLOU Electronics has already implemented multiple energy storage projects in Southeast Asia, building a strong reputation and customer network that will support future market development once the new base becomes operational.

The relevant person in charge of CLOU Electronics stated that the Indonesian energy storage production base is a vital component of the company’s globalization strategy. The release of 3GWh annual capacity will significantly enhance the company’s global supply capability and competitiveness. Going forward, CLOU will use the Indonesian base as a hub to deepen its international market presence, accelerate technological innovation, and provide efficient, reliable, and cost-effective energy storage solutions that support global energy transition under the “dual-carbon” goals.

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.

Victoria Approves 2,200MWh of Battery Storage through Streamlined Pathway in Australia

Source: Energy Storage News

The Tramway Road BESS will be built near Eku Energy’s operational 150MW/150MWh Hazelwood BESS in Victoria (pictured). Image: Eku Energy

The Victoria government in Australia has approved a 300MW/1,200MWh battery energy storage system (BESS) in Gippsland and a 332MW solar PV power plant with integrated storage in the state’s northeast region, via the Development Facilitation Program.

Victoria’s planning minister, Sonya Kilkenny, announced the approvals for Eku Energy’s Tramway Road standalone BESS and the Meadow Creek Solar Farm, which combines a 332MW solar PV plant with a 250MW/1,000MWh battery system.

The projects represent approximately AU$1.2 billion (US$780 million) in combined investment and will create over 650 construction jobs across both developments.

Eku Energy’s 1,200MWh Tramway Road BESS

The Tramway Road BESS will deliver a 4-hour duration storage capacity of 300MW, positioning the facility to provide grid stability services and energy arbitrage opportunities across Victoria’s transmission network.

Located in Hazelwood North, the project will be constructed adjacent to existing transmission infrastructure where developer Eku Energy already operates the 150MW/150MWh Hazelwood BESS at the former Hazelwood Power Station coal-fired power plant.

Eku Energy has numerous projects under development in Australia, while also maintaining a presence in several other international markets. The company, which is jointly owned by Macquarie Asset Management and British Columbia Investment Management Corporation, aims to achieve 9GWh of storage capacity by 2028 and has recently expanded into the New Zealand market.

The Tramway Road facility will connect directly to the transmission network, enabling participation in the National Electricity Market (NEM) ancillary services while supporting the integration of renewable energy across southeastern Australia.

The 1,000MWh Meadow Creek solar-plus-storage site

Meanwhile, the Meadow Creek Solar Farm, located 27km southeast of Wangaratta, is being pursued by energy storage developer and system integrator Energy Vault.

Alongside the solar PV power plant, the project proposal includes a co-located 250MW/1,000MW battery system that would provide additional grid stability services during peak demand periods.

The hybrid project will span 400 hectares of agricultural land and incorporate agrivoltaics principles, allowing continued farming operations beneath and around the solar installation.

The Meadow Creek development was first announced in 2022’s edition of All-Energy Australia, where the developer described the BESS as a 250MW/500MWh system.

The Victoria government’s Development Facilitation Program initiative, which was expanded last year to include renewable energy projects, aims to speed up the development of critical infrastructure projects in Victoria.

Before its inclusion, projects had to pass through the Victorian Civil and Administrative Tribunal, which resulted in around 20% of these projects being delayed by approximately two years.

The Victoria government noted that more than AU$7.8 billion worth of investment across 22 projects has been included in the Development Facilitation Program since it was expanded to include renewables.

Victoria’s energy and resources minister, Lily D’Ambrosio, emphasised the projects’ role in delivering lower energy costs to Victorian households while creating employment opportunities in regional communities.

“Our fast-tracked pathway has unlocked nearly AU$8 billion worth of investment into renewable energy projects – helping provide cheaper and cleaner energy to hundreds of thousands of Victorian households,” D’Ambrosio said.

Other notable BESS projects to have advanced through the initiative in recent months include Chinese PV module manufacturer Trina Solar’s 500MW/1,000MWh Kiewa Valley BESS, which is being developed in the Murray-Darling basin, to the east of Melbourne, the state capital.

Developer ACEnergy also saw its 350MW/770MWh Little River BESS included within the scheme earlier this year.

(By George Heynes)

CENSA Upcoming Events:

1. Dec.4-5 | 2025 China Energy Storage CEO Summit | Xiamen, Fujian

Register Now to attend

Read more: http://en.cnesa.org/new-events-1/2025/12/4/dec4-5-2025-china-energy-storage-ceo-summit

2. Apr. 1-3, 2026 | The 14th Energy Storage International Conference & Expo

Register Now to attend, free before Oct 31, 2025.